Denair High-Pressure Oil-Free Screw Air Compressors

- Can output up to 580 psi

- Oil free

- Rotary Screw Compressor

Regular price

$0.00

- Simple construction Low vibration

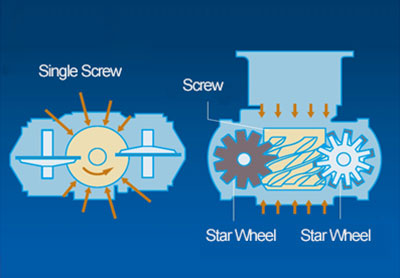

The single screw air compressor uses a single screw and two star wheels, one placed on either side of the screw. Radial and axial loads cancel each other, resulting a theoretically zero load. This is the most advanced designing structure of the single screw air compressor.

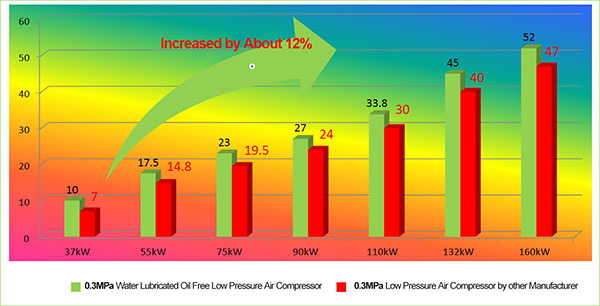

- High efficiency

Firstly, single screw air compressor theoretically doesn't have any clearance volume. Secondly, the water used as a lubricating medium also seals gap inside the compression chamber, and enables high efficient operation at low speeds. Thirdly, using water as a cooling method keep compressor ideal isothermal compression.

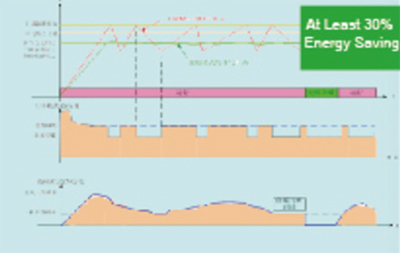

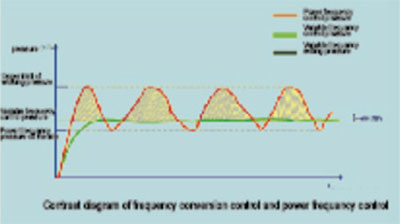

- Energy saving

When the actual air usage is lower than rated air delivery, compressor consumes extra power without any air output during unloading. However, with inverter, compressor changes the rotary speed of motor depending on detected air pressure, resulting energy saving.

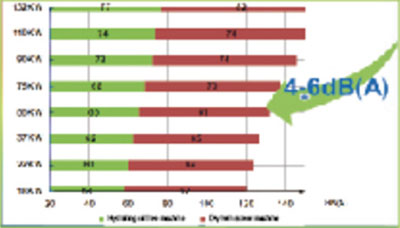

- Less noise

First, the motor and screw are directly connected without any rotation gear to cause gear noise. Meanwhile, sound absorbing materials are also used in the equipment shell to reduce noise.

- Stable air delivery

Depending on the valve of pressure sensor, the digital controller change the motor rotation speed through inverter. That is how it controls the discharge air pressure to make stable air output.

- Monitorable

Intelligent monitoring is used to prevent accidents. Emergency alarm appears on computers and short messages will also be sent to managers. All these are substantial to the prevention of production accidents.