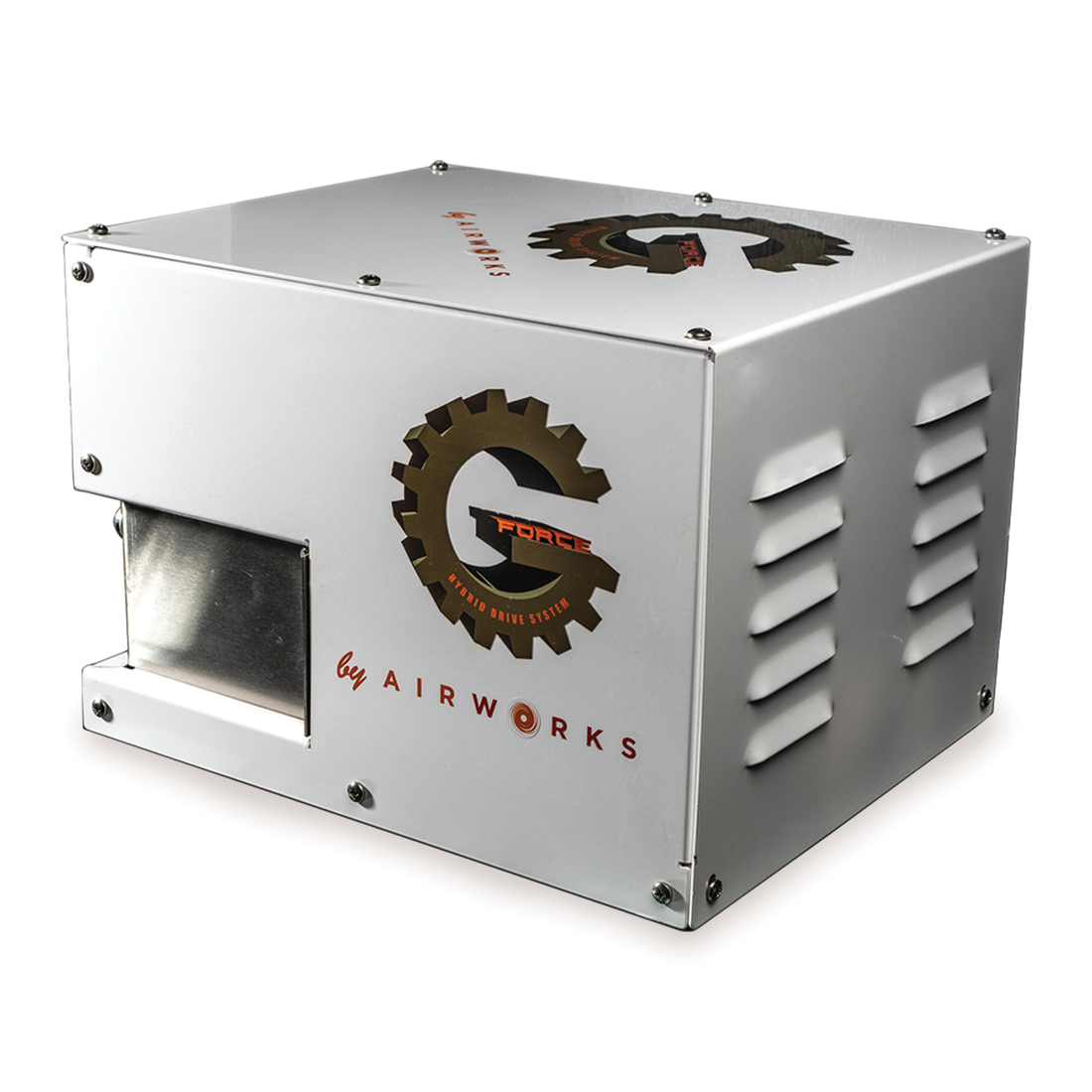

Airworks Cyclone Deflator

Regular price

$0.00

HOW IT WORKS

- The tool operates on compressed air to activate a high volume venturi that creates a vacuum that when activated draws the air from the tire. It operates most effectively using 150-175 CFM of air or 100 -120 PSI at the input gauge.

- As the air is released from the tire and the air pressure decreases, so does the rate of flow. As the air slows to approximately 75 PSI, the deflation tool begins to draw the air at a high rate from the tire until it reaches 0 PSI.

- The tool will decrease both the deflation and inflation times. The tool operates with compressed air, it requires a minimum of 150 CFM air flow, but operates most efficiently at 175 CFM.

- Tests have shown up to a 55% savings in deflation times. This will vary depending on the type of deflation method that is currently being used.